As an efficient, durable, and versatile filter material, sintered mesh features excellent corrosion resistance, high-temperature resistance, and stable filtration accuracy. It is widely used in petrochemical, aerospace, food, pharmaceutical, metallurgy, machinery, power, electronics, etc.

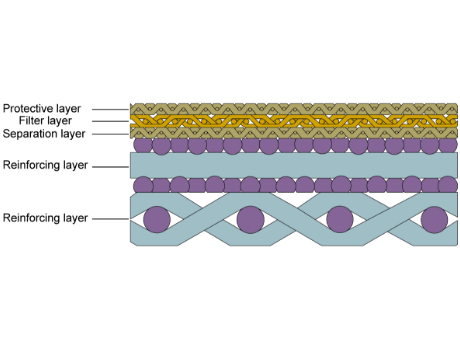

Sintered mesh is generally constructed from multiple layers of same or different stainless steel woven mesh after laminate pressing, vacuum sintering and calendering. It can be fabricated into filter elements in various shapes, such as round, cylindrical, conical, and pleated shapes.

Sintered mesh has strong mechanical strength and overall rigidity, as well as high strength, high-temperature resistance, and excellent chemical stability.

As a company specialized in the development, production, and sales of metal filter elements, we are committed to providing high-quality, high-performance metal filter products and excellent services to our customers. We have a high-quality, skilled R&D team that constantly puts forth new ideas and leads the development of the industry. At the same time, we have advanced production equipment and a strict quality control system to ensure the quality and performance of our products.

We can provide you with a wide range of materials to choose from and produce products that meet your specific needs. In this way, we can provide you with filter element products more suitable for your project.

With our advanced manufacturing technology, we have the capability to provide you with high-precision and high-quality products.