Top cover diameter inspection (can be welded with a cross bar)

Custom No-crossbar perforated filter cylinders are a type of filter elements often used in sewage treatment. They are usually designed and manufactured according to specific customer requirements and applications to ensure optimal filtration effect and performance.

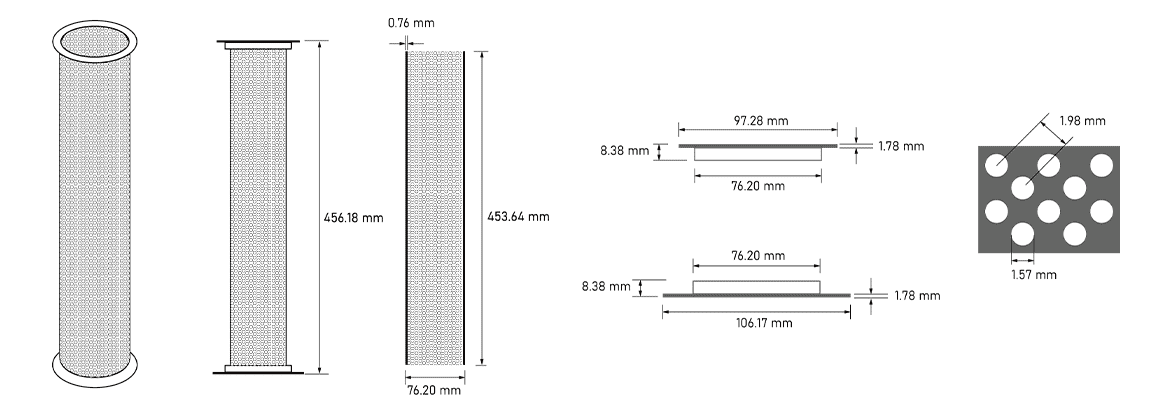

No-crossbar perforated filter cylinders can be customized according to different requirements, such as hole size, hole spacing and plate thickness. These parameters can be adjusted to make these perforated filter elements suitable for different types of sewage treatment processes to achieve the best filtration effect. In addition, we can provide various surface treatments for custom perforated filter cylinders as needed, such as spraying and plating, to improve their corrosion resistance and lifespan.

During the sewage treatment, custom no-crossbar perforated filter cylinders are commonly used as primary filters to remove larger impurities and suspended particles. Their advantages include reusable, easy to clean, less prone to clogging, and have a longer lifespan. In addition, they can be used in conjunction with other filter elements, such as activated carbon filters and ultrafilters, to achieve better filtration results.

Top cover diameter inspection (can be welded with a cross bar)

Bottom cover diameter inspection

Cylinder diameter inspection

Overall height inspection

Foam spacer

Wooden case package

We highly value the needs of each customer, and therefore, we offer customized services to meet your specific requirements. Our professional team can work with you to design and manufacture products that can meet your expectations based on your specific requirements. Besides, we offer a range of customization options, including sizes, materials, and other personalized choices, to ensure that the final product fits your needs perfectly.. If you need customized services, please feel free to contact us, we will serve you wholeheartedly.