Staggered

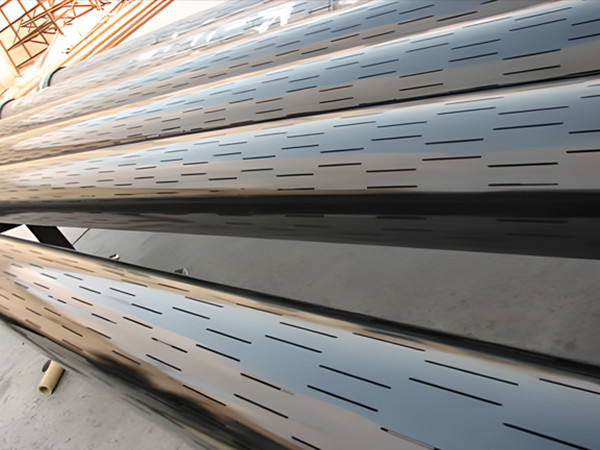

Slotted Liner is used in oil and gas wells with sand particle sizes larger than 0.3 mm to enhance the permeability of the wells. By cutting specific specifications of slots on J55 or N80 oil casing or tubing, we achieve sand filtration while allowing oil and gas to flow through, effectively preventing wellbore blockage. Our slotted liners are suitable for various geological conditions and wellbore sizes, making them a reliable and cost-effective choice to improve the productivity and stability of oil and gas wells.

Slotted Liner Patterns

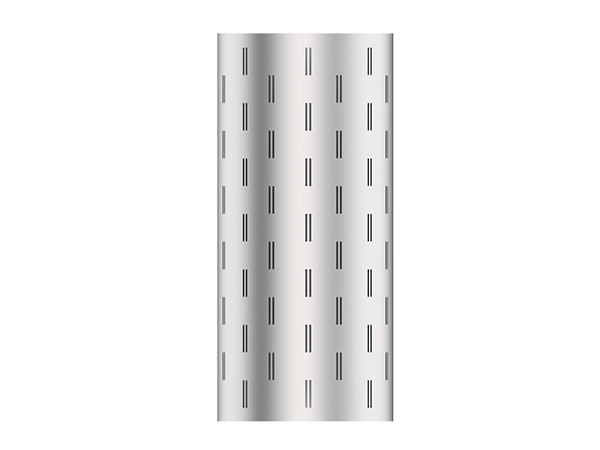

We offer three different slotted liner patterns. Compared to staggered and straight slot patterns, gang slot pattern has superiority over installation torque-loading capacity and substantially improves the liner's resistance to lateral bucking and collapse pressures.

Staggered

Gang

Straight

Slot Shapes

There are two types of slots for slotted liners based on their geometric shapes - straight cut slots and seamed keystone slots. Seamed keystone slots have better performance than typical straight cut slots, but they are slightly more expensive.

Straight Cut Slot

Seamed Keystone Slot

Applications

Staggered slotted liner

Gang slotted liner

Straight slotted liner