Finished polymer melt filter elements in factory

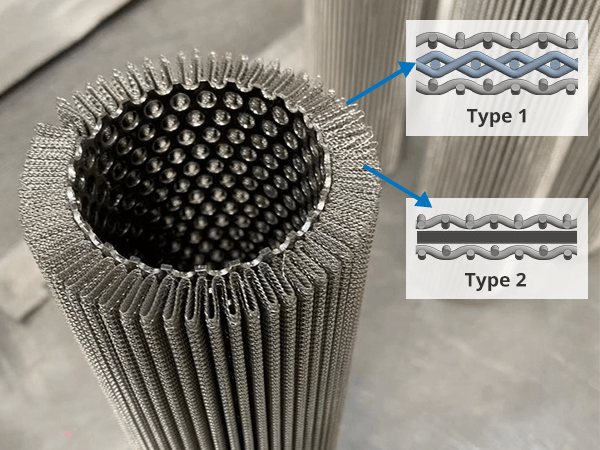

Polymer melt filter element belongs to the common products of polymer filter. It consists mainly of sintered metal fiber felt and metal woven mesh (filter layer).

Sintered metal fiber felt can be made into a multilayer structure with apertures ranging from coarse to fine, with high porosity and high dirt holding capacity. The metal woven mesh is made of stainless steel woven mesh of different diameters. This kind of filter element is not easy to fall off, easy to clean, resistant to high temperatures, economical to use, and has good strength. They effectively remove hard and gel-type pollutants in high pressure, high viscosity polymers.

Polymer melt filter element consists of a perforated tube as a support layer and a filter layer.

The structure of the filtration layer (pleated part) is divided into a protective layer, a filtration layer, and a support layer.

Depending on your specific needs, we offer 2 common types of filter layers:

Finished polymer melt filter elements in factory

Length measurement

Sample sampling

Opening detail

Finished polymer melt filter elements

Polymer melt filter elements display

We offer a customized service for our clients, please contact us, if you need help!