In this case study, we showcase two custom sugar scalping screen mesh solutions, designed specifically for white sugar and refined sugar applications. We can offer various specifications, detailed drawings, applications, and product photos, which emphasize the versatility and effectiveness of our screening solutions in sugar processing applications.

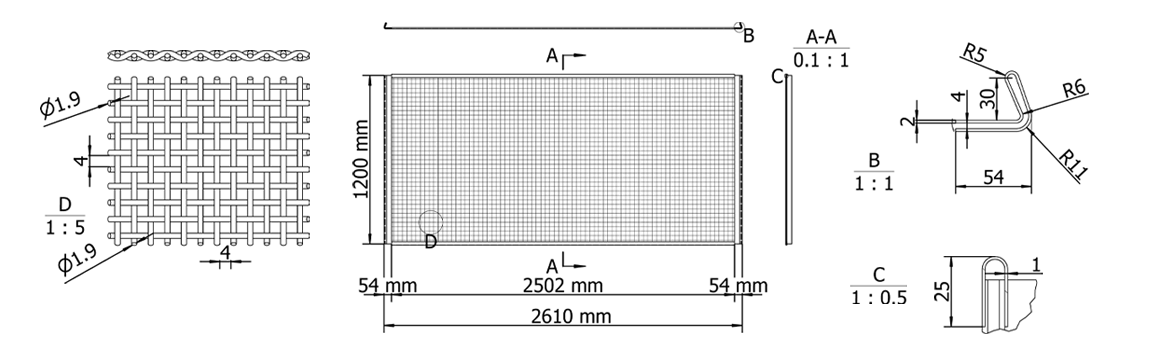

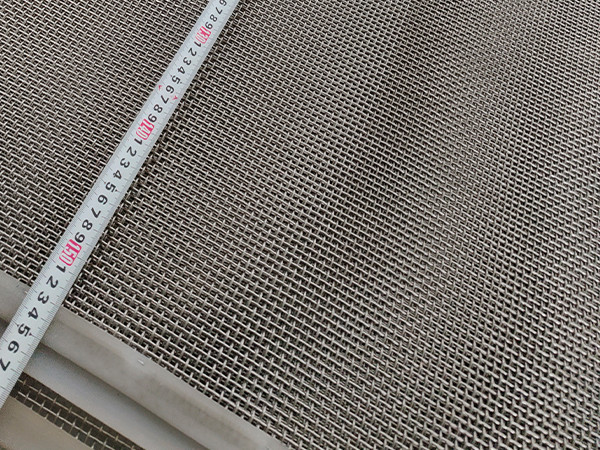

White sugar scalping screen mesh

- Material: Food grade 304

- Length: 2610 mm

- Width: 1200 mm

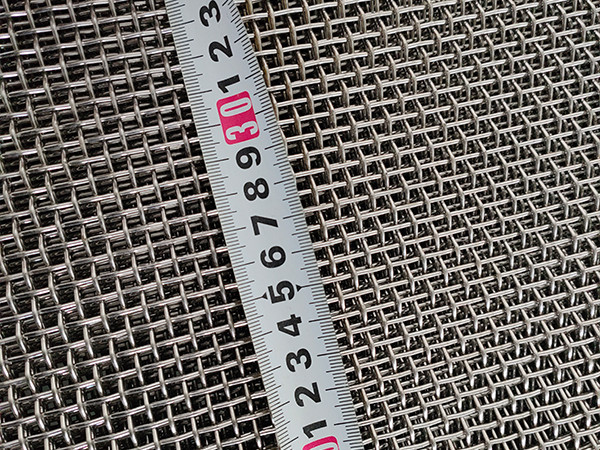

- Aperture: 4 mm

- Wire diameter: 1.9 mm

- Clamp plate size: 54 mm × 31 mm × 45°

- Clamp plate thickness: 2 mm

- Length side material: Food grade PU sheet

- Length side width: 25 mm

- Length side thickness: 1 mm

- Clamp plate is attached with spot welding vertically.

- Food grade PU sheet is affixed by heating horizontally.

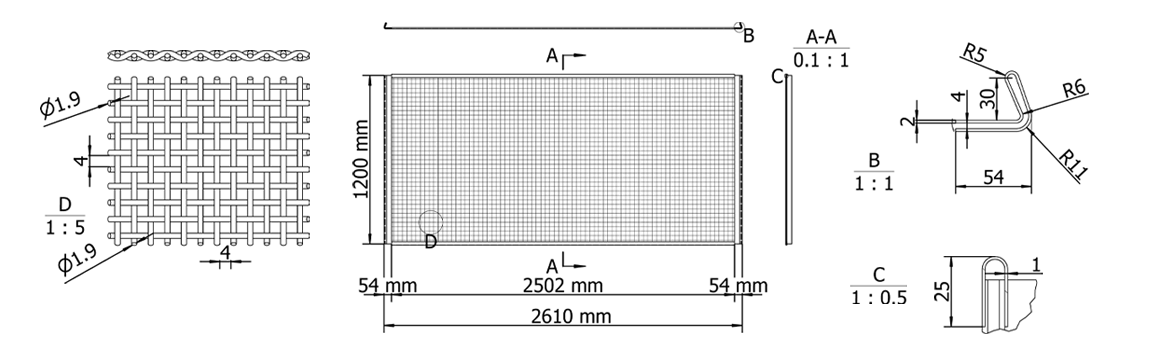

Refinery sugar scalping screen mesh

- Material: Food grade 304

- Length: 3110 mm

- Width: 1550 mm

- Aperture: 4 mm

- Wire diameter: 1.4 mm

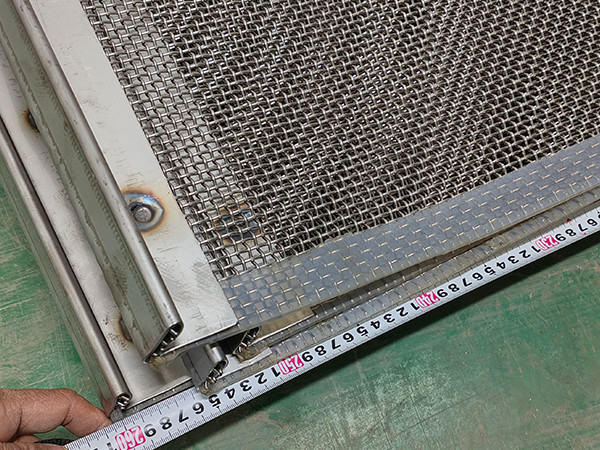

- Clamp plate size: 54 mm × 31 mm × 45°

- Clamp plate thickness: 2 mm

- There are 2 pcs plates welded on each end of the clamp.

- Plates width: 20 mm

- Plates length: 40 mm

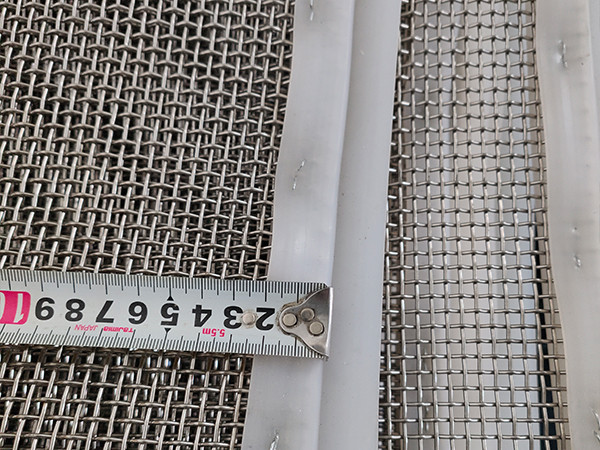

- Length side material: Food grade PU sheet

- Length side width: 22 mm

- Length side thickness: 2 mm

- Clamp plate is attached with spot welding vertically

- Food grade PU sheet is attached by staple pin horizontally.

White sugar scalping screen drawing

Refinery sugar scalping screen drawing

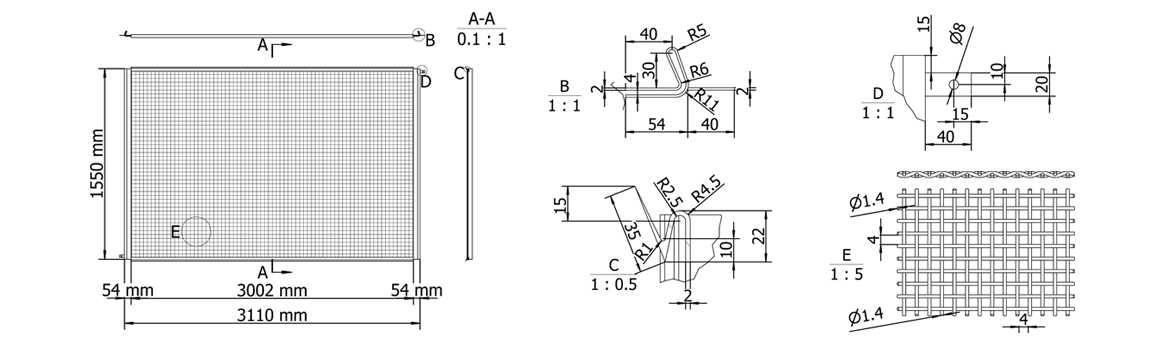

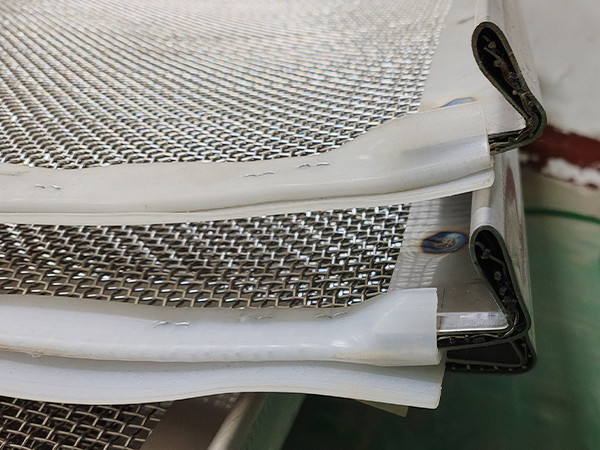

Refinery sugar scalping screen

Clamp plate with welded pieces

Front view of PU sheet attached by staples

Back view of PU sheet attached by staples

PU sheet affixed with heating