Sintered woven wire mesh cartridge with filter basket

In filtration systems, regardless of the media being filtered, the selection of wire mesh filters and the operation and maintenance of wire mesh filters are very important. This ensures high-precision filtering for optimal results.

Nowadays, wire mesh is playing an increasingly diverse and important role in the filtration industry with its unique advantages – cleanability & long service life. This makes the cleanable filter cartridge made of wire mesh more popular than disposable filter cartridges, effectively reducing use and maintenance costs.

So, how do we clean filter cartridges? With over 20 years of experience in the manufacture of filter cartridges, Boedon provides you with the following professional advice:

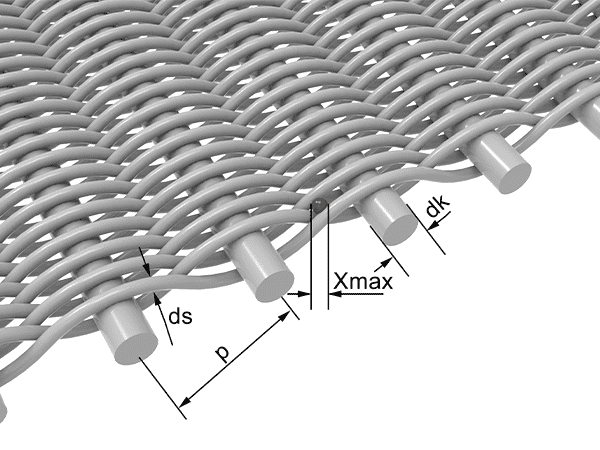

Wire mesh is an important part of wire mesh filter, generally made of high quality stainless steel wire, which is stretched to a specified wire diameter by a drawing machine under specific high temperature process conditions, and then woven by a weaving machine in a constant temperature, dust-free and clean plant. It is characterized by precise structure, uniform mesh, good filtration accuracy and wear resistance, high temperature resistance, strong acid resistance, and corrosion resistance performance.

In order to precisely screen particles in the specified particle size range and meet the specific filtration needs of clients, the mesh, wire diameter, weaving method, layers and alloy composition of the wire mesh can be customized.

Regardless of the filtration process, only effective filtration can be considered successful. However, successful filtration also means unavoidable problems such as mesh clogging and accumulation of impurities. Therefore, it is very important to clean wire mesh filters.

Regular cleaning of wire mesh filters can prevent problems such as mesh clogging and surface buildup, ensuring that the entire filtration system maintains adequate throughput and accuracy over a longer period of time. However, improperly cleaned wire mesh filters can cause damaging backpressure, reduce equipment operating efficiency, and even increase energy consumption.

Sintered woven wire mesh cartridge with filter basket

2-layer perforated filter cartridge

We can consider the following two aspects when choosing the proper cleaning method for wire mesh filters:

Regardless of the filtration process, the filtration efficiency of wire mesh is of utmost importance. To ensure the most accurate filtration, we need to clean it properly on a regular basis.

Boedon continuously adjusts filter specifications to achieve better filtration accuracy. We also increase filtration throughput without sacrificing filtration accuracy, aiming to improve filtration performance and achieve the best filtration effect to provide the best wire mesh filters for your filtration system.

Contact us