Hydraulic filter element

Hydraulic filer element is an important component of the hydraulic system used to filter out particles and rubber impurities in the system and ensure the cleanness of the hydraulic system. As a key part of the filter, hydraulic filter element performs filtration and/or dewatering functions in the filter housing.

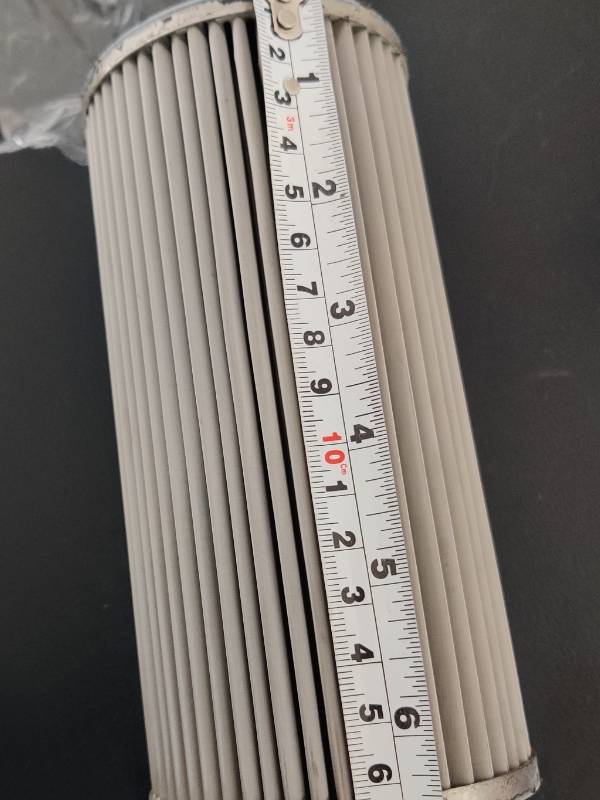

Hydraulic filter element is composed of pleated filtration layers, support layers and end caps. Support layers are located at the innermost part of the filter element while pleated filtration layers surround support layers, forming a stabilizing support cylinder; Both ends of pleated filtration layers and the support layer are well sealed by end caps. In this way, hydraulic filter element can effectively perform actual filtration function and ensure the smooth operation of the hydraulic system.

Hydraulic filter element

Hydraulic filter element end cap

Hydraulic filter element pleated layer

The replacement cycle of hydraulic filter elements depends on many factors, including hydraulic system working conditions, operating conditions, hydraulic oil quality, filter element types and specifications.s

You can replace the filter element based on the working hours of the hydraulic system. Typically, the replacement cycle is every 500 to 1000 hours or every 12 to 18 months.

For the filtration of hydraulic systems of rolling machines and continuous casting machines and the filtration of various lubricating equipment

For the separation and recovery of products and intermediate products in oil refining and chemical production processes, and the filtration of oilfield injection well water and natural gas particles.

For the purification and uniform filtration of polyester melts in the drawing process, protective filtration of air compressors, de-oiling and de-watering of compressed gases.

For the purification of oil in lubrication systems, speed control systems, bypass control systems, feed pumps, fans and de-dusting systems in turbines and boilers.

For the filtration of lubricating oils and engine oils

For the air, oil and fuel filtration of internal combustion engines, hydraulic oil, diesel and water filtration of mechanical equipment, ships and trucks.

We recommend that you observe the components of the hydraulic or lubricating circuits that are most susceptible to contamination and determine the oil cleanliness class, and therefore the filter rating of the entire system. In critical applications, we recommend that you separate the hydraulic and lubricating circuits.

Different element designations, optimized to the respective application, have been generated due to the diversity of application for lubricating and hydraulic filters.

We offer a wide range of filter elements for you to choose from, if you have any question or demand, please feel free to contact us at any time.